Nzira yekudzikisa kurasikirwa kwesimbi mukugadzira engineering

Iyo inonyanya kukosha nzira ndeyekuziva chikonzero chekushandiswa kukuru kwesimbi, ingave iyo magineti density yakakwira kana frequency yakakura kana kuzara kwenzvimbo kwakanyanyisa uye zvichingodaro.Ehe, zvinoenderana neyakajairwa nzira, kune rumwe rutivi, zvinodikanwa kufungidzira chokwadi sezvazvinogona kubva kudivi rekuenzanisa, uye kune rumwe rutivi, iyo nzira yekubatanidza tekinoroji inoderedza kuwedzera kwesimbi kushandiswa.Zvinoenderana neyakajairwa nzira ndeyekuwedzera kushandiswa kweyakanaka silicon simbi pepa, kune akasiyana maapplication mamiriro ane nani chigadzirwa classification.

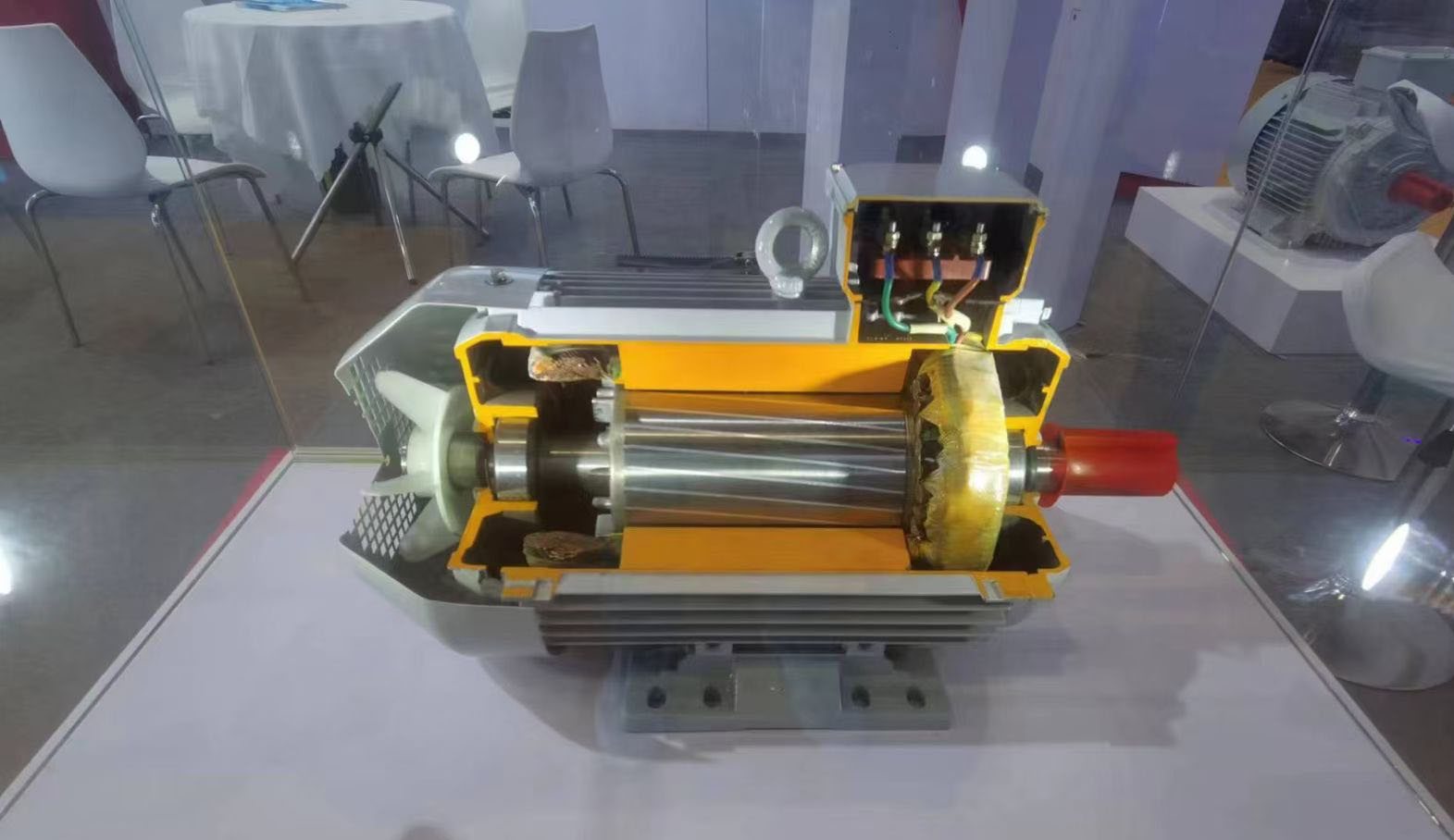

1.Optimized magnetic circuit

Kugadzirisa magineti wedunhu, kunyanya optimize sinusoidal zvimiro zvemagineti.Izvi zvakanyanya kukosha, kwete chete kune yakagadziriswa-frequency induction motors kuita.Variable frequency induction motor synchronous mota yakakosha.Ndakamboita mamotor maviri ane maitiro akasiyana kuitira kuderedza mari muindasitiri yemachira emucheka, hongu, chinhu chinonyanya kukosha ndechekuti hapana danda rakarerekera, zvichikonzera kusawirirana kwe sinusoidal yemhepo gap remagineti.Nemhaka yokuti basa racho riri mumamiriro ekumhanya-mhanya, kushandiswa kwesimbi kunotora chikamu chikuru, saka kurasikirwa kwemamota maviri kwakakura zvikuru, uye pakupedzisira, mushure memamwe makoramu ekuverenga kumashure, nokuti kushandiswa kwesimbi kwemotokari pasi pekutonga. algorithm inopfuura 2 nguva.Zvinokuyeuchidza zvakare kuti kana iwe uchiita frequency kutendeuka inomhanyisa kudzora mota, iwe unofanirwa kubatanidza control algorithm kuti uzviite.

2.Decrease magnetic density

Iyo inonyanya kukosha nzira ndeyekuziva chikonzero chekushandiswa kukuru kwesimbi, ingave iyo magineti density yakakwira kana frequency yakakura kana kuzara kwenzvimbo kwakanyanyisa uye zvichingodaro.Ehe, zvinoenderana neyakajairwa nzira, kune rumwe rutivi, zvinodikanwa kufungidzira chokwadi sezvazvinogona kubva kudivi rekuenzanisa, uye kune rumwe rutivi, iyo nzira yekubatanidza tekinoroji inoderedza kuwedzera kwesimbi kushandiswa.Zvinoenderana neyakajairwa nzira ndeyekuwedzera kushandiswa kweyakanaka silicon simbi pepa, kune akasiyana maapplication mamiriro ane nani chigadzirwa classification.

3.Optimized magnetic circuit

Kugadzirisa magineti wedunhu, kunyanya optimize sinusoidal zvimiro zvemagineti.Izvi zvakanyanya kukosha, kwete chete kune yakagadziriswa-frequency induction motors kuita.Variable frequency induction motor synchronous mota yakakosha.Ndakamboita mamotor maviri ane maitiro akasiyana kuitira kuderedza mari muindasitiri yemachira emucheka, hongu, chinhu chinonyanya kukosha ndechekuti hapana danda rakarerekera, zvichikonzera kusawirirana kwe sinusoidal yemhepo gap remagineti.Nemhaka yokuti basa racho riri mumamiriro ekumhanya-mhanya, kushandiswa kwesimbi kunotora chikamu chikuru, saka kurasikirwa kwemamota maviri kwakakura zvikuru, uye pakupedzisira, mushure memamwe makoramu ekuverenga kumashure, nokuti kushandiswa kwesimbi kwemotokari pasi pekutonga. algorithm inopfuura 2 nguva.Zvinokuyeuchidza zvakare kuti kana iwe uchiita frequency kutendeuka inomhanyisa kudzora mota, iwe unofanirwa kubatanidza control algorithm kuti uzviite.

4.Decrease magnetic density

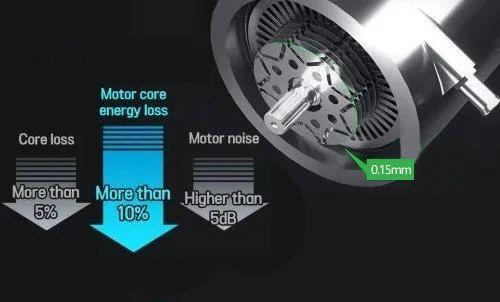

Wedzera kureba kwesimbi musimboti kana kuwedzera iyo magineti conductivity nzvimbo yegineti redunhu kuderedza iyo magineti flux density, asi huwandu hwesimbi hunoshandiswa nemota huchawedzera zvinoenderana;

5.Kuderedza kuwanda kwesimbi chip kuderedza kurasikirwa kweiyo induced current

Kana iyo inotonhora-yakakungurutswa silicon simbi pepa ikashandiswa pachinzvimbo cheinopisa-yakakungurutswa silicon simbi pepa, ukobvu hwesilicon simbi sheet inogona kudzikiswa, asi iyo nhete yesimbi yepakati pepa ichawedzera huwandu hwesimbi machipisi uye mutengo wekugadzira we. mota.

6. Iyo inotonhora-yakakungurutswa silicon simbi pepa ine yakanaka magineti permeability inoshandiswa kuderedza hysteresis kurasikirwa.

7.High performance iron chip insulation coating

8.Kupisa kupisa uye teknolojia yekugadzira

9.Kushungurudzika kwakasara mushure mekugadzira iron chip kuchakanganisa zvakanyanya kurasikirwa kwemotokari, uye nzira yekucheka uye punching shear stress ine simba guru pakurasikirwa kwesimbi yesimbi panguva yesilicon steel sheet machining.Kucheka pamwe nekutenderedza nzira yesilicon simbi pepa uye kupisa kurapwa kwesilicon simbi yekubaya pepa kunogona kuderedza kurasikirwa kwe10% kusvika 20%.

Nguva yekutumira: Nov-27-2023