Nzira yekuderedza kurasa kwerekuru muinjiniya dhizaini

Nzira yakakosha ndeyekuziva chikonzero chekushandiswa kweiyo huru yesimbi, kunyangwe iyo magineti yakakura kana iyo frequency yakakura kana iyo nzvimbo yemunharaunda yakanyanya kuwanda uye zvichingodaro. Ehezve, zvinoenderana nenzira yakajairika, pane rumwe rutivi, izvo zvinofanirwa kufungidzira izvo zvakawandisa sezvinobvira kubva kudivi rekufungidzira, uye kune rumwe rutivi, iyo nzira yekubatira, iyo tekinoroji yekudyidzana inodzora iyo yekuwedzera simbi. Sekureva kwenzira yakajairika ndeyekuwedzera kushandiswa kweakanaka silicon Simbi pepa, kune akasiyana mashandiro ekushandisa isa chigadzirwa chiri nani chigadzirwa chekugadziriswa.

1.optimized magineti wedunhu

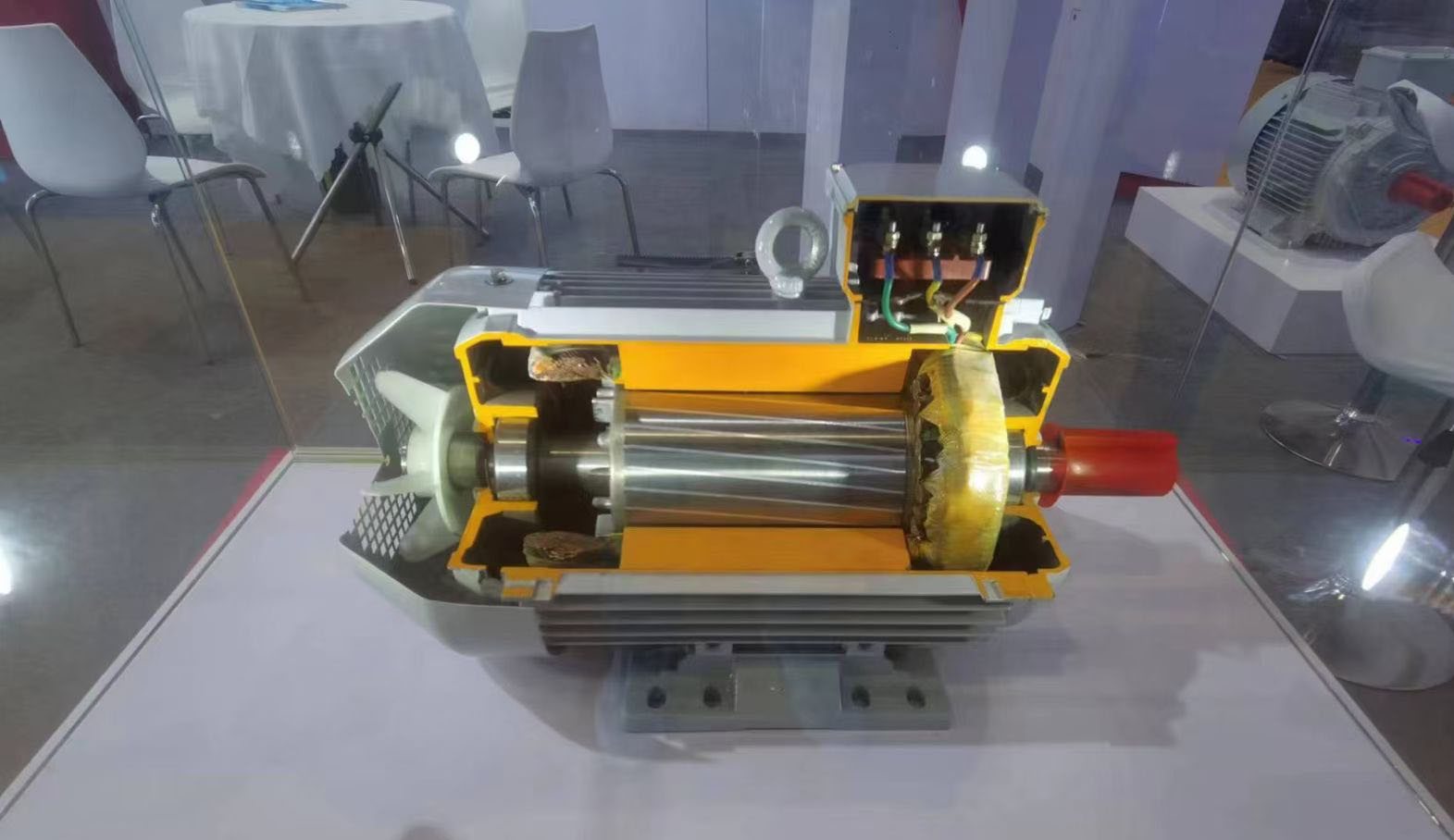

Optimizing dunhu remagineti, zvakananga optimizing zvivakwa zvisingatadzi zveMagineti. Izvi zvinokosheswa, kwete chete kugadzirira-frequency induction motors kuti uite. Variable frequency induction mota synchronous mota yakakosha. Ini ndaimboita motors maviri nekuita kuti kuderedze mitengo muzvinyorwa zvemichero, chokwadi, icho chinonyanya kukosha ndechekuti hapana danda rekusanzwisisika reSinusodal yeMhepo Gapnet Shama. Nekuti basa racho riri mumamiriro ekumhanya zvakanyanya, zvekushandisa zvesimbi zvakakura, saka kurasikirwa kwevafundisi vaviri kwakakura kwazvo, uye pakupedzisira, mushure memamwe mitezo yemotokari pasi peiyo algorithm inopfuura kaviri. Zvinokuyeuchidzawo kuti kana iwe uchiita frequency kutendeuka kwekumhanyisa kudzora mota, iwe unofanirwa kuunganidza algorithm yekuzviita.

2.Decrease magineti density

Nzira yakakosha ndeyekuziva chikonzero chekushandiswa kweiyo huru yesimbi, kunyangwe iyo magineti yakakura kana iyo frequency yakakura kana iyo nzvimbo yemunharaunda yakanyanya kuwanda uye zvichingodaro. Ehezve, zvinoenderana nenzira yakajairika, pane rumwe rutivi, izvo zvinofanirwa kufungidzira izvo zvakawandisa sezvinobvira kubva kudivi rekufungidzira, uye kune rumwe rutivi, iyo nzira yekubatira, iyo tekinoroji yekudyidzana inodzora iyo yekuwedzera simbi. Sekureva kwenzira yakajairika ndeyekuwedzera kushandiswa kweakanaka silicon Simbi pepa, kune akasiyana mashandiro ekushandisa isa chigadzirwa chiri nani chigadzirwa chekugadziriswa.

3.Optimized magineti wedunhu

Optimizing dunhu remagineti, zvakananga optimizing zvivakwa zvisingatadzi zveMagineti. Izvi zvinokosheswa, kwete chete kugadzirira-frequency induction motors kuti uite. Variable frequency induction mota synchronous mota yakakosha. Ini ndaimboita motors maviri nekuita kuti kuderedze mitengo muzvinyorwa zvemichero, chokwadi, icho chinonyanya kukosha ndechekuti hapana danda rekusanzwisisika reSinusodal yeMhepo Gapnet Shama. Nekuti basa racho riri mumamiriro ekumhanya zvakanyanya, zvekushandisa zvesimbi zvakakura, saka kurasikirwa kwevafundisi vaviri kwakakura kwazvo, uye pakupedzisira, mushure memamwe mitezo yemotokari pasi peiyo algorithm inopfuura kaviri. Zvinokuyeuchidzawo kuti kana iwe uchiita frequency kutendeuka kwekumhanyisa kudzora mota, iwe unofanirwa kuunganidza algorithm yekuzviita.

4.co.kcrease magineti density

Wedzera kureba kweiyo simbi core kana kuwedzera iyo magineti yekuita nzvimbo yenzvimbo yemagineti yekudzikisa magineti flux density, asi huwandu hwesimbi unoshandiswa nemotokari inowedzera saizvozvo;

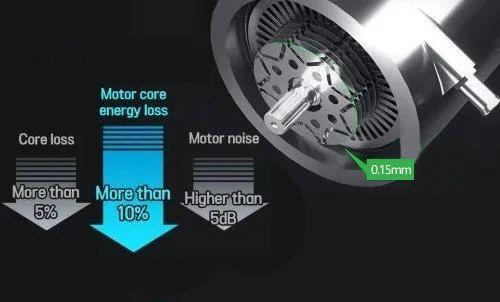

5.Rededuce ubvu hwesimbi chop kuti uderedze kurasikirwa kwekukonzerwa kwazvino

Kana iyo inotonhora-yakatonhora silicon simbi simbi inoshandiswa pane iyo inopisa simbi simbi simbi inogona kuderedzwa, asi iyo yakatetepa yesimbi yeiyo inowedzera huwandu hwechipisi chesimbi uye mutengo wekugadzira wemota.

6

7.High performance iron chip insulation yekukanda

8.Heat kurapwa uye kugadzira tekinoroji

. Kucheka munzira yekungocheka yeiyo silicon simbi pepa uye kupisa kurapwa kweiyo silicon Steel punching pepa kunogona kuderedza kurasikirwa kwe10% kusvika 20%.

Kutumira Nguva: Nov-27-2023